What Is the Latest Technology for the Garment Decoration Industry?

In today’s ever-evolving world, technology continues to shape various industries, and the garment decoration industry is no exception. With advancements in digital printing, automation, and innovative materials, the garment decoration industry has witnessed a significant transformation in recent years. This article explores the latest technology that are revolutionizing the garment decoration industry, providing new opportunities for customization, efficiency, and creativity.

Introduction

The garment decoration industry encompasses various techniques and technologies used to add designs, patterns, and personalization to clothing items. Traditionally, methods like screen printing and hand embroidery were prevalent, but recent technological advancements have introduced cutting-edge techniques that offer greater flexibility, precision, and efficiency.

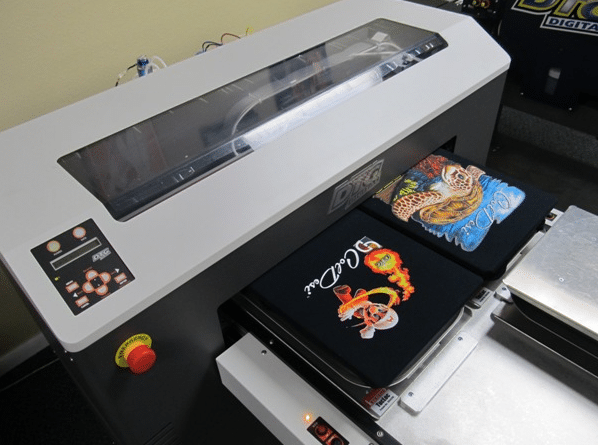

The Latest Technology for the Garment Decoration Industry Direct-to-Garment (DTG) Printing

DTG printing has gained immense popularity in recent years. This technique involves printing designs directly onto garments using specialized inkjet printers. DTG printers can produce intricate designs with a wide range of colors, gradients, and fine details. This technology enables quick turnaround times, especially for small batch productions, and offers the flexibility to print on various fabric types.

The Latest Technology for the Garment Decoration Industry Sublimation Printing

Sublimation printing involves transferring ink onto fabric using heat and pressure. It allows for vibrant and long-lasting prints that are resistant to fading or cracking. Sublimation printing is particularly suitable for synthetic fabrics and is widely used in sportswear, activewear, and promotional apparel. The technology provides excellent color reproduction and allows for all-over printing, covering the entire garment with the desired design.

Laser Cutting and Engraving

Laser cutting and engraving technologies have Laser machines can precisely cut fabric, leather, and other materials, offering intricate and complex designs with clean edges. They are also capable of engraving patterns, logos, or text onto garments, adding a unique touch to the design. Laser technology allows for fast production, customization, and high levels of accuracy.

Embroidery Machines

Embroidery machines have become more advanced, enabling intricate and detailed designs to be stitched onto garments. Computerized embroidery machines can automatically reproduce complex patterns with multiple colors and textures. This technology offers versatility and high-quality results, making it a preferred choice for adding logos, monograms, or decorative elements to garments.

Heat Press Machines

Heat press machines utilize heat and pressure to transfer designs onto garments. They are commonly used for applying vinyl, heat transfer vinyl (HTV), and other heat-applied materials. Heat press technology allows for customization and personalization, making it popular for creating custom t-shirts, jerseys, and other promotional items. It offers durability and versatility, with the ability to apply designs to various fabric types.

3D Accessories

3D printing has made significant advancements in the garment decoration industry, particularly for the production of accessories and embellishments. It allows for the creation of intricate and unique designs, such as buttons, buckles, and jewelry, using a range of materials. 3D printing provides endless possibilities for customization and enables designers to push the boundaries of creativity.

Smart Textiles and Wearables

The emergence of smart textiles and wearables has brought a new dimension to the garment decoration industry. These textiles are embedded with electronic components, sensors, or conductive materials, enabling functionalities such as temperature regulation, heart rate monitoring, and even interactive displays. Smart textiles provide opportunities for innovative designs and integration of technology into clothing items.

Automation and Robotics in Production

Automation and robotics have greatly influenced the garment decoration industry by streamlining production processes and improving efficiency. Automated systems can handle tasks such as fabric cutting, pattern placement, and quality control. Robotics technology ensures precision and consistency, reducing human error and labor costs while increasing productivity.

Augmented Reality (AR) and Virtual Reality (VR)

Augmented Reality (AR) and Virtual Reality (VR) technologies are making their way into the garment decoration industry, enhancing the design and purchasing experience. AR allows customers to visualize how garments will look on them or in their desired environment before making a purchase. VR enables designers to create virtual prototypes and simulate different fabric prints and patterns, saving time and resources.

Sustainable and Eco-Friendly Solutions

With growing environmental concerns, the garment decoration industry is embracing sustainable and eco-friendly solutions. Technologies such as water-based inks, eco-solvent printing, and dye-sublimation methods reduce the environmental impact of production processes. Additionally, the use of recycled materials and implementing energy-efficient practices contribute to a more sustainable industry.

Enhancements in Software and Design Tools

Software and design tools play a crucial role in the garment decoration industry. The latest advancements in design software allow for greater precision, efficiency, and creativity. Designers can create intricate patterns, manipulate colors, and visualize the final product more accurately. Integration with production systems facilitates seamless workflows and reduces time-to-market.

Integration of Internet of Things (IoT)

The Internet of Things (IoT) has started to make its mark in the garment decoration industry. IoT devices can collect data throughout the production process, enabling real-time monitoring, quality control, and predictive maintenance. This integration improves operational efficiency, reduces waste, and enhances overall productivity.

Enhanced Quality Control Systems

Quality control is paramount in the garment decoration industry. The latest technologies have introduced advanced quality control systems that can detect flaws, irregularities, or inconsistencies in fabric or prints. Automated inspections ensure high-quality standards are met, minimizing the chances of defective products reaching the market.

Conclusion

The garment decoration industry is continually evolving, driven by technological advancements that enhance customization, efficiency, and creativity. From digital printing techniques like DTG and sublimation printing to innovative technologies such as laser cutting, embroidery machines, and 3D printing, each innovation offers unique possibilities for garment decoration. Additionally, the integration of smart textiles, automation, and sustainable practices paves the way for a more efficient and environmentally conscious industry.

FAQs

Q1: How does DTG printing compare to traditional screen printing?

DTG printing offers greater flexibility and detail compared to traditional screen printing. It allows for full-color prints, intricate designs, and is more suitable for small batch productions.

Q2: Can laser cutting machines work with delicate fabrics?

Yes, laser cutting machines can handle delicate fabrics with precision. They offer clean cuts without fraying and are capable of creating intricate designs.

Q3: What are the advantages of using heat press machines for garment decoration?

Heat press machines provide versatility and durability. They allow for customization on various fabric types and offer long-lasting prints.

Q4: How can smart textiles benefit the garment industry?

Smart textiles bring innovative functionalities to garments, such as temperature regulation and interactive displays. They offer opportunities for unique designs and enhanced user experiences.

Q5: What role does IoT play in the garment decoration industry?

IoT integration enables real-time monitoring, quality control, and predictive maintenance. It improves operational efficiency and productivity in the industry.