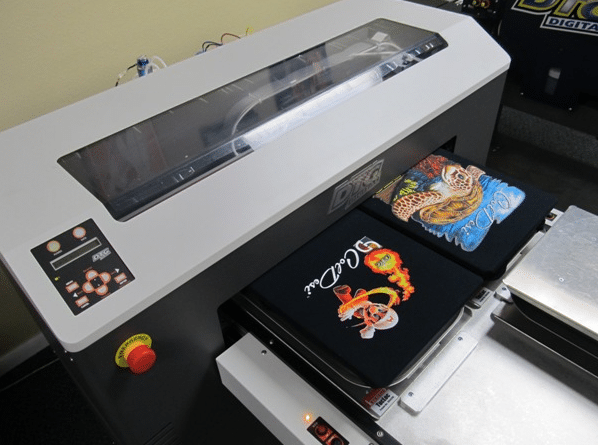

DTF (Direct to Film) printing involves printing a design onto a special film, applying adhesive powder, and then heat-pressing it onto fabric. This method allows the ink to bond securely to the garment surface, making it suitable for many fabric types and colours.

DTF printing works on cotton, polyester, blends, nylon, and synthetic fabrics. Because the design adheres through an adhesive layer rather than soaking into the fabric, it performs consistently across light and dark garments.

When properly applied, DTF prints are highly durable and can withstand repeated washing without cracking, peeling, or fading. The flexibility of the adhesive layer helps the print move naturally with the fabric.

DTF printing offers more fabric versatility than DTG and allows complex, full-colour designs without the thick layers associated with vinyl. It combines strong colour output with better flexibility across different garment types.

Yes. DTF printing is efficient for single custom pieces, small batches, and bulk orders. It does not require screen setup or fabric pretreatment, making it cost-effective and scalable for different order sizes.